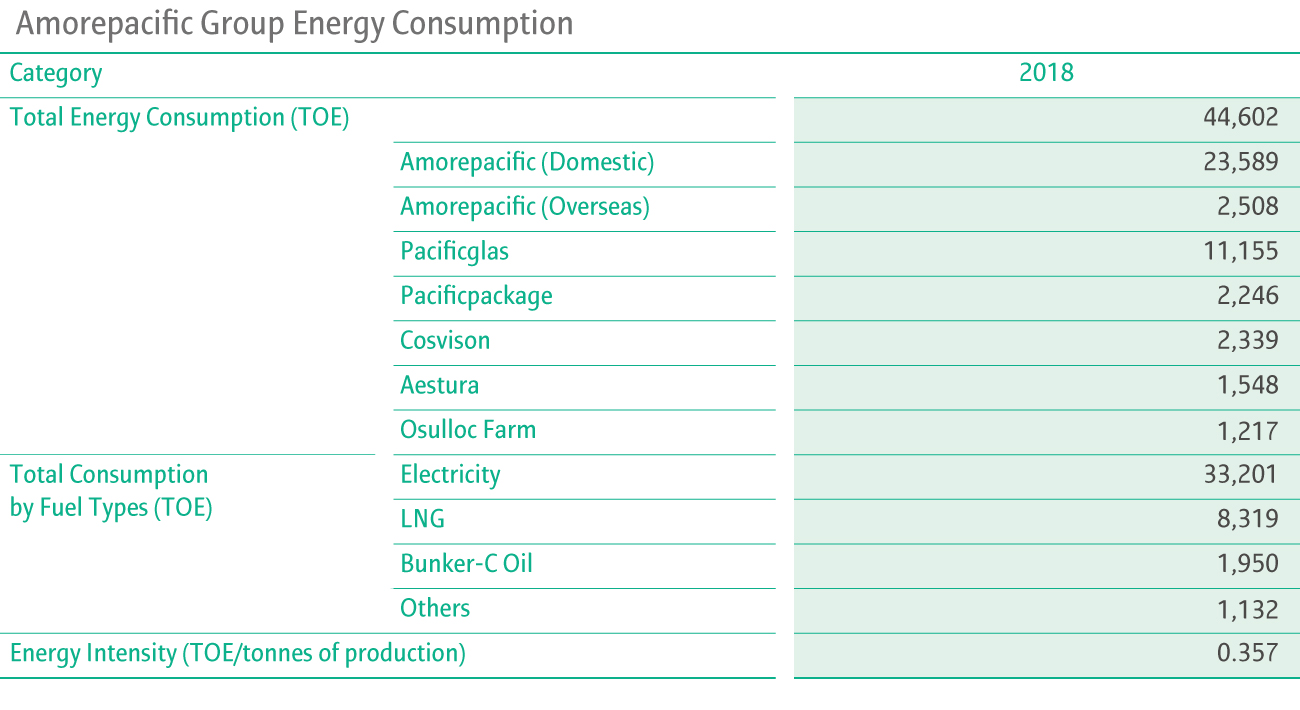

Amorepacific is continuously investing in renewable energy and introducing it with a goal to expand the energy generation by renewable energy in the long term. In 2018, the domestic energy generation by renewable energy reached 3,881MWh, twenty-five times bigger than the previous year. 12% of energy used at the new headquarters building and 4.4% of energy consumed by Amorepacific business sites were from renewable energy sources. Amorepacific Group will keep expanding the ratio of renewable energy in the future.

The global headquarters of Amorepacific Group is certified as the first grade of G-SEED (Green Standard for Energy and Environmental Design), the first grade of energy efficiency, and gold grade of LEED (Leadership in Energy and Environmental Design) by various Korean organizations and standards. The building is designed to consume 37.6% less energy than its energy demand projection.

The global headquarters building is operating renewable energy facilities (solar panels, geothermal and solar power), heat recovery ventilation system, high-efficiency transformers and motors, power factor correction capacitors, and 100% LED lighting. Moreover, the building is equipped with DALI (Digital Addressable Lighting Interface) system that senses the natural level of light and automatically adjusts brightness of the interior of the building. Since Amorepacific Group employees moved in on December 2017, employees are also participating in energy saving activities by adjusting operation hours of lighting and heaters at offices and using power outlets that automatically block standby power.

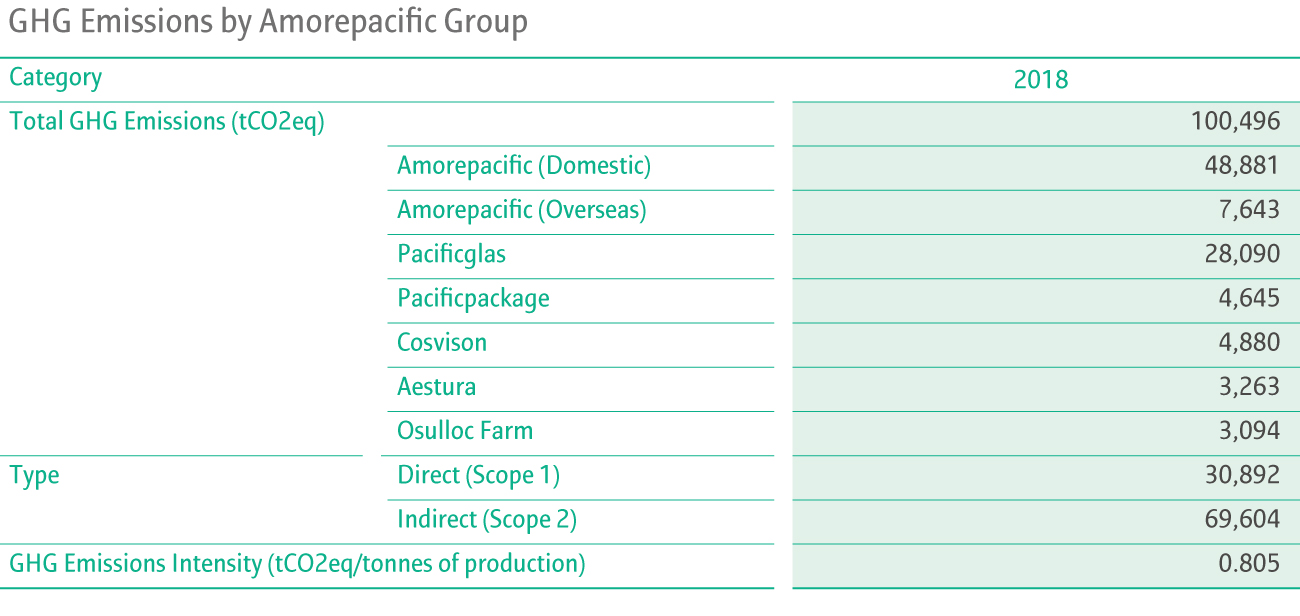

Amorepacific Group continuously identifies and implements tasks to reduce GHG emissions in our production sites. Although the GHG emissions increased by 7.4% in 2018 due to the expansion of FnC building at Daily Beauty sites and construction of the second site in Shanghai, a total of 1,880 tonnes of GHG emissions were reduced thanks to 43 GHG reduction measures including cold water production facility using the natural temperature during the winter, AI-powered lighting system for corridors, and installation of heat recovery instrument of air pollution prevention facilities. Moreover, we share a notable energy reduction case through our internal cross-functional task force on climate change.

Amorepacific Group’s central distribution center replaced lighting with high-efficiency LED lighting and optimized the operation of heating and cooling facilities. In 2018, distribution centers in Osan and Gimcheon enhanced energy efficiency by improving filters of heating and cooling units and installing shades over outdoor heat exchangers, reducing 191 tonnes of GHG emissions.

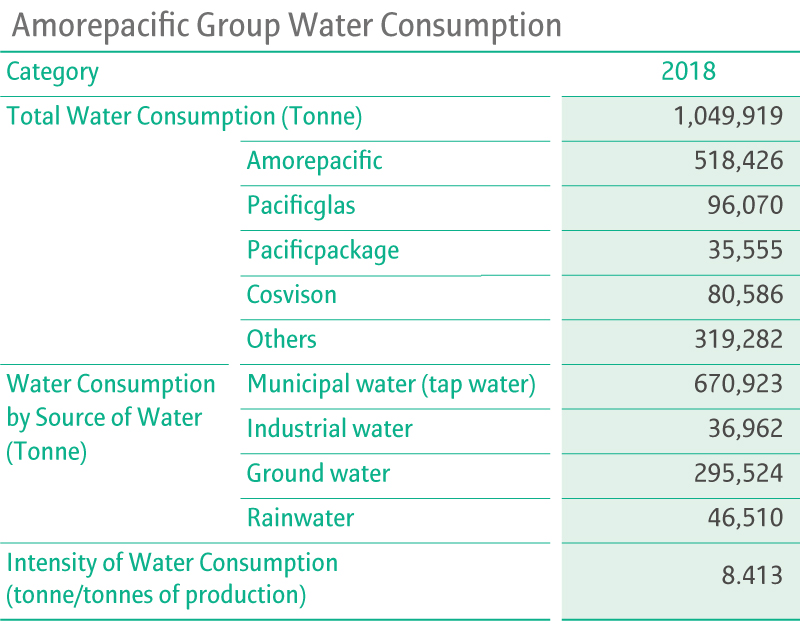

Amorepacific Group is deeply aware of the need for efficient use of water resource, optimizing its water consumption under the principle of 3R – Reduce, Recycle, and Reuse. On a 2015 baseline, Amorepacific Group aims to reduce water consumption per tonne of production by 22% in Korea and 41% overseas by 2020.

In 2018, water consumption was increased as the Group increased the number of product cleansing to achieve higher quality standards. However, a number of counter-measures were taken, including the use of rainwater as water for laundry, examination of water leakage during holidays, adjustment of the flow rate of cooling water of vacuum pumps, and improving the production and cleansing processes.

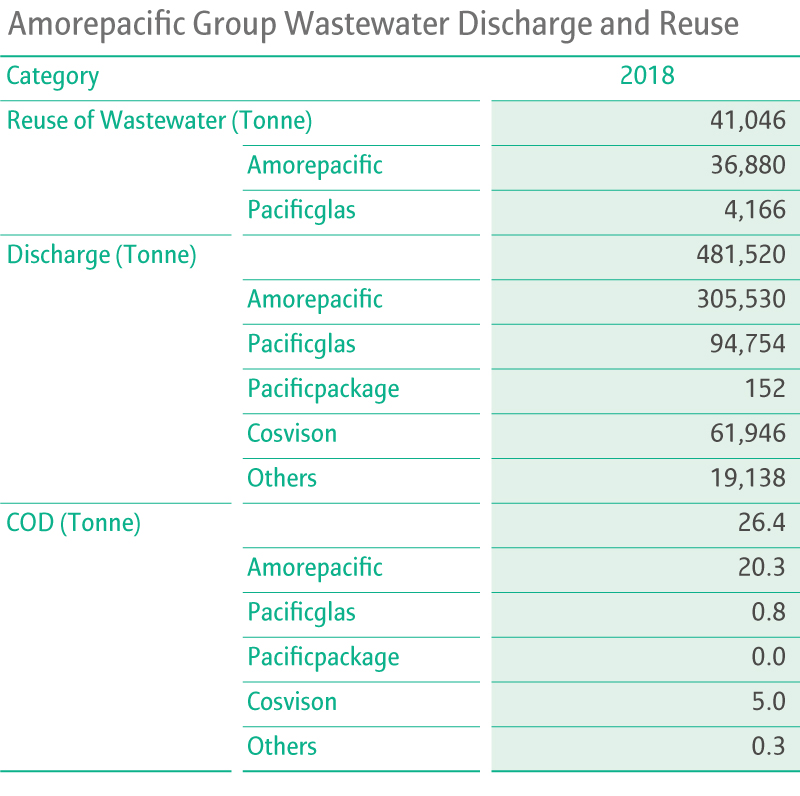

Amorepacific Group also tries to minimize the impact of effluent water discharged from its business sites on adjacent ecosystems. In particular, the Group reuses wastewater such as cleaning water for landscaping and introduces a wastewater recycle system by replacing filtering system at wastewater processing facilities, inspecting toxic chemical processing facilities, and expanding automation systems. In 2019, Amorepacific Group will increase the use and application of rainwater as well as dry processing in production and manufacturing processes.

Amorepacific Group seeks to contribute to building a circular economy by minimizing waste generated in production sites and promoting recycling. Waste generated in each production site is categorized by types and traits, while optimal recycling measures are implemented for each type of waste. In 2018, Amorepacific Group reduced 5,448 tonnes of waste compared to the previous year. The recycle rate also increased by 22%. Moreover, the Group is increasing the number of products that are designed to be recycled from the initial production stage. In 2019, waste compressors will be installed for optimal management of waste.